Dry mortar production line is used for producing dry mortar, it main consists of the following parts: material store silo, sand dryer, screw conveyor, weighing system, hoist machine, pre-mix silo, mixer, final product silo, packing machine, dust collector, air-phase balance system, control system.

The productivity is 5-50T/h.

According to the layout type, it can be classified into tower type and series type.

Its up to the customers workshop area.

1. What is dry mortar?

Dry mortar is also called pre-mixed mortar, which made in the factory by precise batching and uniform mixing. It can be used directly just by adding water in construction site. It has different properties though adding different additives. The demand for dry mortar has increased rapidly due to its outstanding merit compare to the mortar made in job-site.

2. Type of dry mortar:

2.1. Bonding mortar: masonry mortar, wall and floor tile adhesive mortar, pointing mortar, anchorage mortar etc.

2.2. Decoration mortar: plaster mortar, inner and outer wall putty, colorful decoration mortar etc.

2.3. Protection mortar: water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, insulation mortar, sound absorption mortar, repair mortar, mildewproof mortar, shielding mortar etc.

3.Raw materials of dry mortar:

3.1. Cementing material: cement, lime, plaster.

3.2. Aggregate: yellow sand, quartz sand, limestone, dolomite, expanded perlite etc.

3.3. Mineral admixture: industrial byproduct, industrial slag, fly ash, pozzolana, fine silica powder etc.

3.4. Water-retention and thickening material.

3.5. Chemical additives.

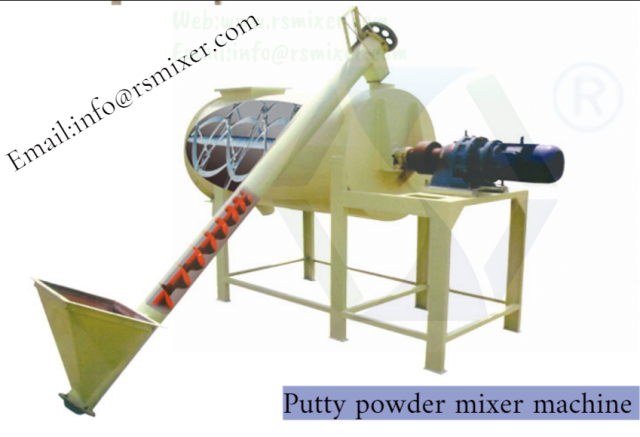

Dry mortar production line consists of bucket elevator, mixing silo,

mixing machine, finished product storehouse, electrical control cabinet,dust collector, steel platform, etc.

1) Masonry mortar

2) Thin and smooth wall mortar

3) Hand-plastering screeding mortar

4) Colored coating mortar

5) Water-proof mortar

6) Plaster powder

7) Wall plastering mortar

8) Ceramic tile adhesive mortar

9) Self-leveling mortar

10) Heat-preservation mortar